Seamless Pigging Operations, Engineered for Safety and Efficiency

T Triangle designs and manufactures a wide range of pig launchers and receivers built to meet the operational and safety requirements of today’s pipeline systems. Whether you’re working with crude, gas, or multiphase flowlines, we deliver equipment that integrates smoothly into your network and performs reliably across both temporary and permanent pigging operations.

What We Deliver

Our pigging systems are designed and fabricated to meet global standards such as ASME VIII, ASME B31.3, PD5500, and PD8010. We provide:

-

Custom-designed pig launchers and receivers for both topside and subsea applications

-

Support for single or multiple pigging operations, tailored to system length and service

-

Optional fitment for pig locks, pig stops, and pig signallers to ensure safe and verifiable operations

-

Pre-commissioning, installation, training, and recertification support across all delivery stages

Built for Demanding Environments

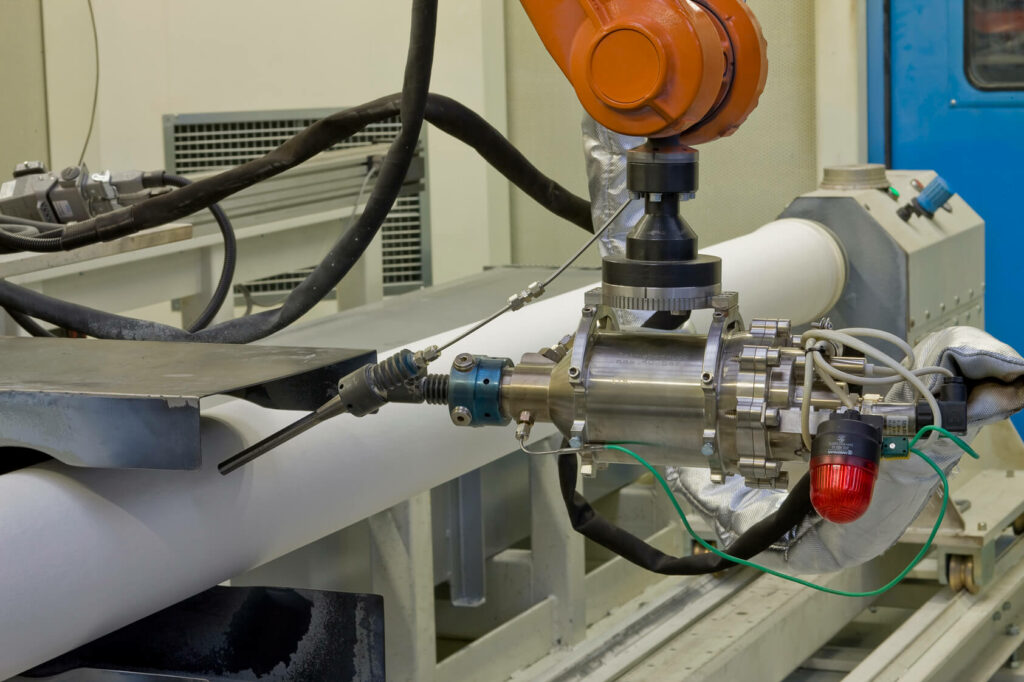

Our pigging systems are built with rugged field use in mind. From fabrication to testing, each unit is prepared to operate under real pressure and exposure conditions, including offshore humidity, high-pressure gas, and corrosive service environments. Launchers and receivers are factory-tested for body integrity, seat sealing, torque control, and pull-head load limits to guarantee safety and reliability during every run. We also supply units with full traceability and documentation for clients operating in regulated regions.

Why It Matters

What’s Included

Real Equipment. Real Field Result

Why T Triangle

Quality

Commitment

Our Clients Trust Us Because:

We know the systems and the environments they run in

We handle both small urgent needs and complex, multi-vendor projects

We’re trained by top OEMs and follow global standards